In today’s life, tin boxes and cans have become a ubiquitous and inseparable part of our lives. Gifts such as tin boxes for Chinese New Year and holidays, mooncake iron boxes, tobacco and alcohol iron boxes, as well as high-end cosmetics, food, daily necessities, etc., are also packaged in tin cans made of printed tin. Looking at these exquisitely crafted tin boxes and cans that resemble handicrafts, we cannot help but ask, how are these tin boxes and cans produced. Below is a detailed introduction to the manufacturing process of tin boxes and cans for printing tin cans.

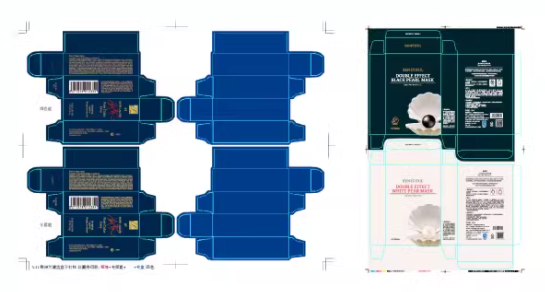

1、 Overall design

The appearance design is the soul of any product, especially packaging products. Any packaged product should not only provide maximum protection for its contents, but also attract customers’ attention in appearance, so design is particularly important. The design drawings can be provided by the customer, or the canning factory can design according to the customer’s requirements.

2、 Prepare tin material

The general production material for tin boxes and cans made from printed tin is tinplate, also known as tin plated thin steel plate. Generally, after confirming the order, the most suitable tin material, tin material variety, size, etc. will be ordered according to the layout diagram. The tin material is usually stored directly in the printing factory. As for the identification of the quality of the tin material, it can be visually inspected to see if there are scratches, uniform patterns, rust spots, etc. The thickness can be measured with a micrometer, and its hardness can be felt by hand.

3、 Mold making and sampling

The mold room makes product molds according to the design drawings and hands them over to the production department for trial production of samples. If they are not qualified, the molds need to be repaired until the samples are correct before mass production can proceed.

4、 Typesetting and printing

It should be noted here that the printing of tin materials is different from other packaging printing. It is not cutting before printing, but printing before cutting. Both the film and layout are sent to the printing factory for typesetting and printing. Usually, a sample is provided to the printing factory for color matching. During the printing process, it is important to pay attention to whether the printing color matching can keep up with the sample, whether the positioning is accurate, whether there are stains, scars, and so on. The printing factories responsible for these issues can generally control them themselves. Some canning factories also have their own printing factories or printing equipment.

5、 Tin cutting

Cut the printed tin material on the cutting lathe. In the actual canning process, cutting is a relatively simple step.

6、 Stamping

That is to say, the tin material is pressed into shape on a punch press, which is the most important step in canning. Usually, a can needs to be completed in multiple processes

Tips

1. The general process of the two-piece can with a lid is as follows: lid: cutting, trimming, and winding. Bottom cover: cutting – flash edge – pre roll line – roll line.

2. The process of sealing the bottom of the lid (bottom cover) can includes the following steps: cutting, trimming, winding, and can body: cutting, pre bending, corner cutting, forming, bone fastening, body punching (bottom cover), and bottom sealing. The bottom process is: cutting materials. In addition, if the metal can is hinged, then there is an additional process for both the lid and the body: hinges. In the stamping process, tin material is usually the most consumed. It is important to pay attention to whether the work operation is standardized, whether there are scratches on the surface of the product, whether there are batch seams on the winding line, and whether the buckle position is fastened. The usual practice is to arrange for the production of bulk samples before production, and produce according to the confirmed bulk samples, which can reduce a lot of trouble.

7、 Packaging

After the stamping is completed, it enters the final stage. The packaging department is responsible for cleaning and assembling, putting into plastic bags, and packing. This stage is the final work of the product, and product cleaning is very important. Therefore, before packaging, it is necessary to do a good job of cleaning, and then package according to the packaging method. For products with multiple styles, the style number and box number must be arranged correctly. During the packaging process, attention should be paid to quality control to minimize the flow of defective products into the finished product, and the number of boxes must be accurate.

Post time: Feb-07-2025