Flat printing process for tin cans:

The biggest feature of lithography is that the printed pattern (ink stained part) and the non printed pattern are on the same plane. Lithography is the process of printing ink onto rubber rollers and then onto tinplate using a pressure roller. Because the printing plate does not directly come into contact with the tinplate ink and does not get dirty, it is suitable for high-quality printing, even if the tinplate has poor smoothness, it will be overcome.

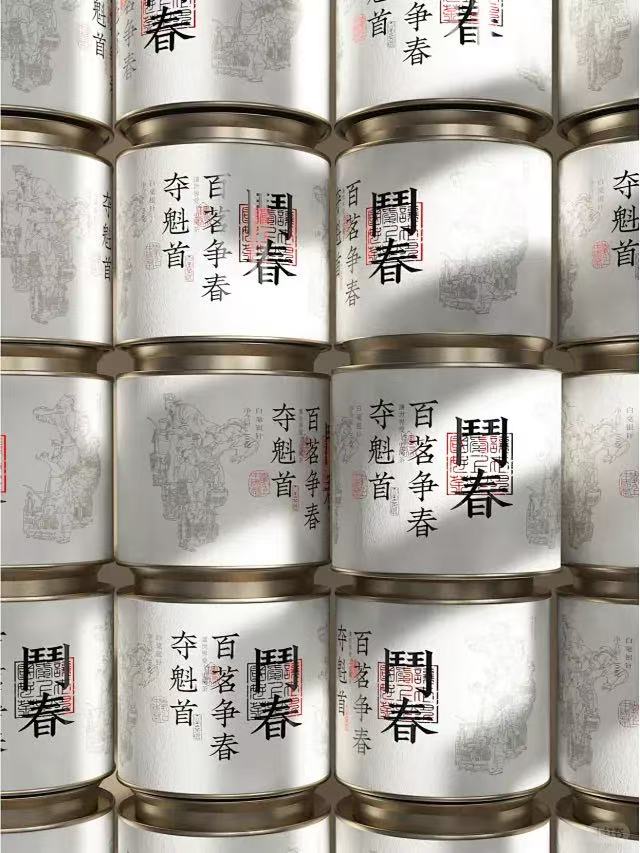

The hot stamping process of tin cans:

After heating the tinplate, the post-treatment process of using tin foil to separate patterns and imprint them on the tinplate has been widely used due to its vivid visual effect.

The letterpress printing process for tin cans:

Letterpress printing refers to the situation where the graphic and textual parts of the page are higher than the non graphic and textual parts. The ink on the ink roller can only be transferred to the graphic and textual parts of the page, while the non graphic and textual parts do not require ink, thus completing the printing process. A traditional printing technique that involves rolling ink onto a tin plate and stamping it onto the tin plate. The pressure applied to the tin plate can be adjusted as needed to create a deeper three-dimensional effect.

Ink free embossing process for tin cans:

No heating, no tin foil, no ink sticking; A processing technique that directly imprints on tinplate, suitable for presenting the original texture of tinplate or expressing it in a minimalist style.

UV printing process for tin cans:

After being irradiated with ultraviolet light with special ink, it will dry and print, suitable for non drying tinplate or other flat materials such as aluminum products, wooden boards, etc.

Screen printing process for tin cans:

Screen printing is a method of hollowing out the printed area on a printing plate and transferring ink through the mesh holes. When the substrate is made of materials such as tinplate, aluminum plate, plastic, or curved surfaces such as boxes or cans, or when there are special printing requirements such as floating surface effects, screen printing is mostly used.

Flat printing process for tin cans:

Flat printing is currently a relatively mature printing method, which is a fast and stable large-scale printing technology suitable for large-scale printing of tinplate cans. It is a very good and economical choice in situations where the printing volume is large.

Screen printing process for tin cans:

Screen printing is a traditional process of printing using a nylon wire mesh. In metal printing, only a single color or a few colors can be used for register printing. Because it belongs to semi manual production, if there is color overlap, it is not suitable for products with high precision requirements.

Screen printing technology for tin cans

The surface of the tinplate can body needs to be pre treated after silk printing. The pre-treatment process of the surface of iron cans, also known as pre press processing. The pre-treatment methods for the surface of iron cans include degreasing, polishing, wire drawing, oxidation, sanding, painting, etc. This method can be used separately or in combination according to the different requirements of the product and the condition of the underlying material to achieve the desired effect.

Post time: Nov-25-2025