Bagged tea has developed rapidly due to its advantages of “quantity, hygiene, convenience, and speed”, and the global bagged tea market is showing a rapid growth trend.

As a packaging material for tea bags, tea filter paper should not only ensure that the effective ingredients of the tea can quickly diffuse into the tea soup during the brewing process, but also prevent the tea powder in the bag from infiltrating into the tea soup. After years of development, the material of tea filter paper has gradually transitioned from gauze, filter paper, nylon, PET, PVC, PP and other materials to corn fiber.

Corn fiber, also known as polylactic acid (PLA) fiber, is derived from renewable plant resources such as corn, potatoes, and crop straw. It has good biocompatibility and biodegradability, antibacterial properties, and breathability. It can not only be used to make biodegradable non-woven tea bags, but also applied in the wet papermaking field to produce food packaging paper such as tea bags, coffee bags, and filter paper.

So, focusing on the performance characteristics of the material itself, what are the main advantages of using PLA fiber in wet papermaking?

1. The material is natural and can come into contact with food

The raw material of polylactic acid fiber comes from renewable plant resources. As a certified food safety material, polylactic acid fiber can be widely used in various types of food, pharmaceuticals, and some high demand household paper applications. Taking the application of tea bags and coffee filter paper as an example, putting them directly into hot water without the precipitation of plastic or other harmful substances is more friendly to the human body.

2. Biodegradability

Taking the application of tea bags as an example, a large number of disposable tea bags are consumed worldwide every day. Tea bags made from traditional materials have a very long degradation cycle, which will bring significant pressure to the natural ecology. However, tea bags or other products made from polylactic acid materials have excellent biodegradability.

Polylactic acid fiber non-woven fabric products can be completely decomposed into carbon dioxide and water by microorganisms in natural environments with certain temperature and humidity, such as sand, silt, and seawater. Polylactic acid product waste can be completely decomposed into carbon dioxide and water under industrial composting conditions (temperature 58 ℃, humidity 98%, and microbial conditions) for 3-6 months; Landfilling in conventional environments can also achieve degradation within 3-5 years.

3. Can be mixed with wood pulp or other natural fibers for use

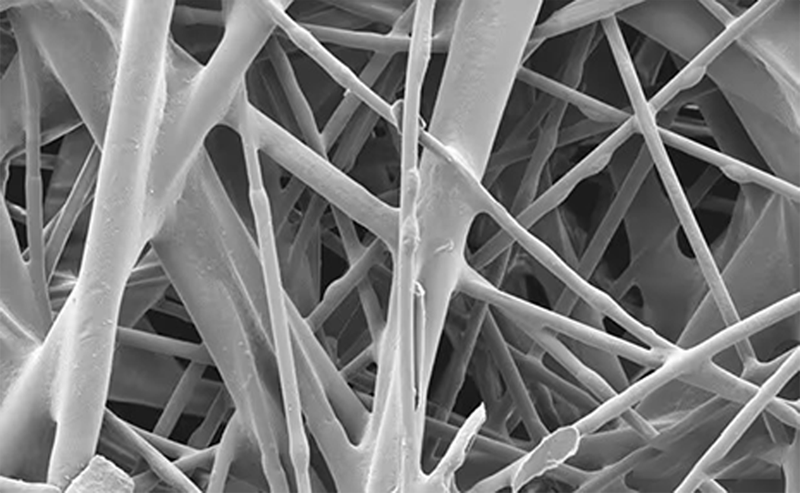

Polylactic acid fibers are usually mixed in a certain proportion with wood pulp fibers, nanofibers, etc. to make pulp and paper. Polylactic acid mainly plays a role in bonding and strengthening, by connecting other fibers through heat and temperature to achieve the purpose of framing and strengthening. In addition, by adjusting the slurry ratio and processing method, it can meet the differentiated needs of different scenarios.

4. Ultrasonic thermal bonding can be achieved

By using polylactic acid fibers to make pulp and paper, ultrasonic thermal bonding can be achieved in subsequent production, which not only saves labor and reduces costs, but also improves production efficiency.

5. Filtering performance

The tea filter paper made of polylactic acid fiber has good filtration performance and high wet strength, which can effectively retain tea leaves and other solid particles, while allowing the taste and aroma of tea to fully penetrate.

In addition to tea filter paper, polylactic acid fiber can also be used in traditional Chinese medicine packaging filter paper, coffee filter paper, and other food packaging paper.

Post time:Jun-04-2025